- Ceramics[109]

- Refractory[12]

- Catalyst[16]

- Carbon[1]

- Water Treatment[25]

- Home Textile Product Machinery Parts[2]

- Exhaust System[9]

- Refrigeration & Heat Exchange Parts[1]

- Gas Disposal[4]

- Contact Person : Ms. Yi Carrie

- Company Name : Jiangxi Pingxiang Xinxing Chemical Environment-Friendly Packing Manufacturer

- Tel : 86-799-7085599

- Fax : 86-799-7085788

- Address : Jiangxi,Pingxiang,Xiabu Industrial Park,Xiangdong District, Pingxiang 337000,P.R.C

- Country/Region : China

- Zip : 337000

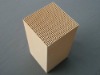

Alumina Brick

Detailed Product Description

Alumina Lining Brick are high grade milling media made by advanced cool isostatic pressing technology and fired at high temperature.

In order to catch the rapid increasing demand of grinding media and provide full series to customers, we have developed grinding media with 90% Al2O3, 92% Al2O3 ,95% Al2O3 and 99% Al2O3. The technical data of each series is listed as following table.

With overwhelming merits in higher density, more regular shape, easily classifying and assorting, superior grinding efficiencies and competitive price prior to natural cobblestones and conventional grinding media, Alumina grinding media is excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Cm3.

Technical Index of Lining Brick

Item | 90series | 92series | 95series | 99series |

Al2O3 (%)

| 90 | 92 | 95 | 99 |

Compressive Strength(KN/Grain) | 9 | 11 | 13 | 15 |

Bulk Density (g/ cm3)

| 2.80 | 3.0 | 3.1 | 3.2 |

Water Absorption( %) | 7 | 6 | 5 | 5 |

Color | White | White | White | White |

Application | Glaze or Tile body Milling | Glaze or Tile body Milling | Glaze or Tile body Milling | Glaze or Tile body Milling |

Raw Materials | Calcined Alumina | Calcined Alumina | Calcined Alumina | Calcined Alumina |

Forming method | CIP | CIP | CIP | CIP |

RECTANGLE (STRAIGHT) Brick

Length | 150 | 150 | 150 | 150 | 150 |

Width | 50 | 50 | 50 | 50 | 50 |

Height | 40 | 50 | 60 | 70 | 100 |

TRAPEZOID (TILTED)BRICK

Length | 150 | 150 | 150 | 150 | 150 | |

Width | W1 | 45 | 45 | 45 | 45 | 45 |

W2 | 50 | 50 | 50 | 50 | 50 | |

Height | 40 | 50 | 60 | 70 | 100 | |

Note: Length in 75mm, 37.5mm, 18.75mm are all available.

Width 58/50mm means upper width is 50mm, and the bottom width is equal to 58mm.

Calculation Method for Alumina Lining Brick

Rectangle bricks used on end face

GA=3.14×r2÷ (L1×W)

GA: Amount of rectangle brick r: radius of cylinder (cm)

L1: Length of lining brick (cm) W: width of lining brick (cm)

HALF RECTANGLE BRICKS USED ON END FACE

GB=D÷W

GB: Amount of half rectangle brick D: diameter of cylinder (cm)

W: width of rectangle brick (cm)

DOSAGE OF RECTANGEL BRICKS AND TRAPEZOID BRICKS ON CYLINDER OF TUBE BODY

GC=R1×R2

R1=3.14×D÷W

GC: overall amount R1: rank amount on cylinder

R2 Amount of one rank D: diameter of cylinder (cm)

R2= (L-2h) ÷L1

H: height of brick (cm) L: length of cylinder (cm)

W; width of lining brick (cm) L1: length of lining brick (cm)

Correct installation method

1. Before installation, all the partial remaining bricks, cement and rust on the inner surface should be cleared, Uneven parts should be patched, and the smooth surface be made hoarse to increase the cohesion with cement.

2. The installation gap should be within 1mm, using425 white cement and 107 glue as adhesive.

The installation should begin with the end faces; two end faces are both made up of rectangle bricks and half rectangle bricks. After the installation of end faces, then for cylinder installation, the cylinder is installed above all, then the trapezoid bricks followed, and so on alternate to ensure the bottom of bricks cling to the inner wall of the cylinder closely. If the rectangle bricks can not be installed properly, the flake bricks can be used to fill up and white cement is used to fill in the gap.