- Ceramics[109]

- Refractory[12]

- Catalyst[16]

- Carbon[1]

- Water Treatment[25]

- Home Textile Product Machinery Parts[2]

- Exhaust System[9]

- Refrigeration & Heat Exchange Parts[1]

- Gas Disposal[4]

- Contact Person : Ms. Yi Carrie

- Company Name : Jiangxi Pingxiang Xinxing Chemical Environment-Friendly Packing Manufacturer

- Tel : 86-799-7085599

- Fax : 86-799-7085788

- Address : Jiangxi,Pingxiang,Xiabu Industrial Park,Xiangdong District, Pingxiang 337000,P.R.C

- Country/Region : China

- Zip : 337000

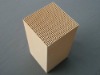

Porcelain Sand Filter

Detailed Product Description

Based on previous ceramic sand filter, we developed a new filter, with the characteristic of large specific surface; strong decontamination capacity; high water yield; long filter cycle, Ceramic Sand Filter effectively solves industry effluent and urban sewage. Aiming at conventional products defect, and in the opinion of new filter development, we adopt porcelain clay; agglomerate; pore-forming agent and CRE, through heating agglomeration, it shows white color; hard texture; even-grained; high porosity and good roundness. It is applicable for Chemical Plant; Oil Refinery; Electric Power; Pharmaceutical Factory; Galvanization; Paper Mill and Brewery filed.

The advantage as follows

1. Big voids on the surface of ball, normally, its filtering velocity is 15-20m3/h, with small head loss; it lowers filtering tanks height and saves electric power and infrastructure expense.

2. Because of even and regular in particle size, making it easy to be cleaned, the back-flush strength is 12-20 l/m2, so the water consumption could be reduced 30-50.

3. Large surface area and pore volume; strong decontamination capacity, generally with 910kg/m3, it is as 1.2 ~ 1.5 times as quartz sand filtering.

4. High strength; small abrasion; usage life is over 15 years.

5. Well distributed; easily packed; uneasy to wash away; none secondary pollution; it is applicable for ion exchange, mechanical filter, valveless filter chamber, reverse osmosis system. It is usually pretreatment or supporting layer in reverse osmosis system which used for supporting layer of activated carbon adsorption.

6. According to water quality and special fabrication processing, the porcelain sand filter material is able to free from iron, Mn, fluorine.