- Ceramics[109]

- Refractory[12]

- Catalyst[16]

- Carbon[1]

- Water Treatment[25]

- Home Textile Product Machinery Parts[2]

- Exhaust System[9]

- Refrigeration & Heat Exchange Parts[1]

- Gas Disposal[4]

- Contact Person : Ms. Yi Carrie

- Company Name : Jiangxi Pingxiang Xinxing Chemical Environment-Friendly Packing Manufacturer

- Tel : 86-799-7085599

- Fax : 86-799-7085788

- Address : Jiangxi,Pingxiang,Xiabu Industrial Park,Xiangdong District, Pingxiang 337000,P.R.C

- Country/Region : China

- Zip : 337000

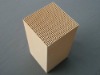

Ceramic Structured Packing with Five Interlink

Detailed Product Description

Light ceramic packing Brief Product Introduction Multi-pore packing (i.e light ceramic packing) was developed by the Anshan Refractory Institute of the Ministry of Metallurgy, North China Civil Engineering Institute and Tianjin University. It is a new type structured packing and featured in Jiangxi Province's 'Sparkle Project' in 1994 and it has won many local and national prizes. It is widely used in naphthalene washing, benzene washing, ammonia washing, de-sulphurization and de-carbonation. It has many advantages over other packaging materials when used in hot water saturation towers and direct cooling towers. Customers have praised it extensively.

Multi-pore packing has a large mass-transfer co-efficient, large valid area and excellent effectiveness. Tests conducted by Tianjin University have shown that the coefficient of multi-pore packing is 2.2 times higher than holo-ceramic packing. When packed, multi-pore packing overlaps with neighboring packing by six supporting legs, thereby constructing a void area. Gas and liquids are transferred over the parting plane. Multi-pore packing has many honeycomb-like microscopic pores that extend the available specific to 99.5%. Although there are other types of packing available, they are less efficient. This product is most effective when used in separation.

Multi-pore packing can resist aging, sudden heat and sudden coldness. Its fire-proofing rate is 1400oc , and it is acid resistant, thus can be used for a long time and is not easily aged. A gas plant in Hefei has applied multi-pore packing since1991, and until now has not required changing. Compared with multi-pore ceramic packing, plastic packaging costs less, but plastic ages easily and can't resist high temperatures. Carbon steel packaging can't be used in conditions that have corrosive media, and stainless metal packing has a higher cost.

Multi-pore packing has a new structure that can make circular shapes, is able to be cut and easy to pack. Also, 100% of the packing plane can be used. Some other kinds of packing can't be cut, so it is inevitable that there are holes around the inner part of the tower, and it's possible that wall flow and channeling occur. The success of using such materials will be affected to different extents. Multi-pore packing successfully eases the contradiction between air gap rate and specific area, it doesn't cause tower blockages and is very efficient, so it's the best choice of those people who want to purchase packing tower

| Product Name | Type | Opposite Edge Distance mm | Height of Supporting Beam mm | Pore Diameter mm | Specific Area m2/m3 | Void Volume % | Staking Weight kg/m3 | Number of Stacking Blocks n/m3 |

| Toothed Ring | XX-1 | 205 | 15 | 60 | 124 | 79 | 330 | 220 |

| Cloverleaf Ring | XX-2 | 194 | 15 | 62 | 102 | 64 | 440 | 215 |

| Cloverleaf Ring | XX-3 | 194 | 15 | 62 | 97.2 | 66 | 420 | 215 |

| Cloverleaf Ring | XX-4 | 194 | 15 | 60 | 74.4 | 71 | 310 | 215 |